Bottom Job, Continued and Continued and

Continued!

I removed all the red bottom paint and some of the blue with stripper

and a DA sander with a 6" pad and 80 grit paper. In the

process of doing that, I sanded through a blister enough that water

came out. Uh oh, the water in the blisters was between the mat

and the fiberglass core. I grabbed the Dremmel and poked about

2,000 holes in every round high spot. This resulted in

identifying an estimated 400 wet blisters,

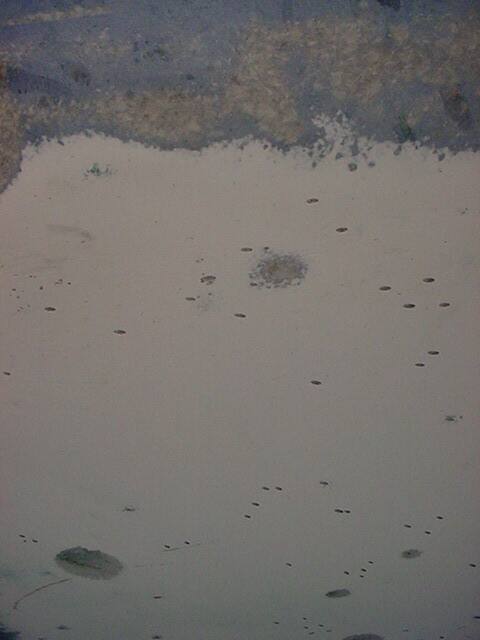

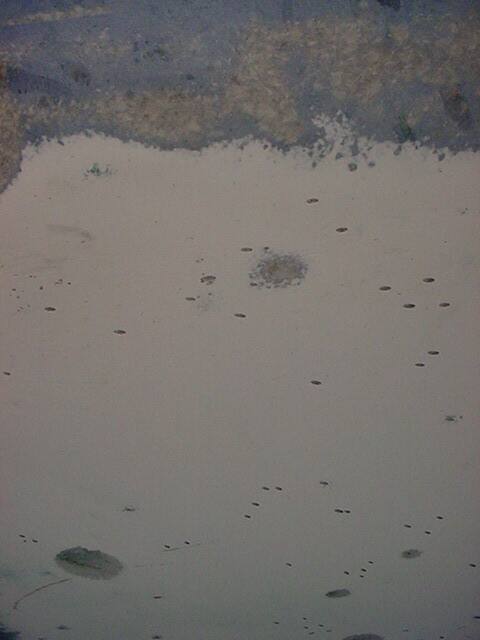

I have now opened as many of the blisters as I know about. As

Rumsfeld

says, "I have not opened up any blisters I do not know about!" In

these pictures you get an idea of how many test holes I had to drill

with the Dremel.

I opened

the blisters up with a Roto-zip with a router attachment on it and

fiberglass bits. I wore out 4 bits grinding them out. This

gets the boat to the condition shown on the right, with much blue paint

remaining.

In the picture below, some of the largest blisters are shown. By

grinding out the mat around all the water, I cute the dry out time from

months to weeks. Indeed, the blisters dried out in only 2 weeks

if I ground out all the wet mat. After that same 2 weeks,

blisters that had only been opened with the Dremel still had about 1/3

the water still in them.

The blisters are determined to be dry enough by taping a piece of Saran

Wrap over the blisters and letting it sit overnight. If any

moisture remains in the blister, it will readily show on the

Saran Wrap. Pretty low tech, but effective.

It took about 35 hours to get to this point! Now that I know how

to use the stripper, I could cut that down by about 10 hours. The

secret on the stripper is to swab it on thick. Then let it

sit for about 20 or 30 minutes. I used a piece of cardboard to

catch the scrapings and contain them so I didn't end up sitting in

them.

BE SURE TO WEAR EYE PROTECTION when messing with the stripper. I

ended up using 2 pairs of gloves. When putting the stripper on I

used two of the cheap latex gloves. When scrapping it off I used

a latex glove topped with a cloth glove to keep from cutting the latex

glove.

Once the stripper got most of the bottom paint off, I switched to the

DA sander. I tried using a half face respirator and

goggles. That is just not sufficient to keep dust out of one's

eyes. I coughed up the $100 for a full face mask from Grainger

that allows me to work as long as I want without getting anything in my

eyes! A painter's head sock is mandatory as is a Tyvek

coverall. Any place not covered is going to get covered with

toxic bottom paint.

When I started grinding on the fiberglass, I thought I was going to

itch forever! A box fan sure helps to remove the dust!

The next step is to remove the rest of the bottom paint with an air

file.long board sander and 36 grit paper. The air file is 17"

long. It

takes one sheet of paper to go from one side to the other. That

also takes about 2 hours! This is pretty demanding physical work

for a CPA! I have been at it every night since 4/15th and my arms

are now in good enough shape that I have to wait for the air compressor

to catch up. Accordingly, this process could move along quicker

with a bigger air compressor. As it is, I will be one half done

in another 3 or 4 hours. It will take another 6 to 10 hours

to finish the other side. Total time at that point will be

about 50 hours.

Note in the picture to the right I used the DA sander to remove all the

gelcoat around the waterline where is was covered with pox. After

removing the gelcoat with the DA sander, I used the air file to fair

it. This curved area will require much hand sanding with a

long board that is flexible enough to bend around the hull.

I will likely let the blisters dry some more while I get to work on

other stuff. Hopefully, they'll all be dried out in another

couple of weeks. Then I get to fill them, fair them with the long

board and spray a coat of primer to see how well I've done sanding up

to that point!

Bob Keim

S/V The Pursuit, #6195

Nashville, TN